The Storm Is Coming

It’s hard to believe it’s been 15 years since we started making the Hurricane. Even in its 15th year we sold over a hundred of them. A fast hull is a fast hull, but a lot has changed since I designed the canoe. When I started designing the Storm I had very specific goals in mind. I wanted a boat that could compete in flat water but excelled in rough water. I wanted a canoe that worked well for larger paddlers. Finally, I wanted it to be comfortable.

Over the last two years we built three prototypes, modified each of them several times, studied hours of video, and did a lot of testing in flat and rough water. When testing prototypes against other designs we spent a lot of time switching back and forth between the canoes. Often it’s very difficult to tell which boat is really faster. But at some point, you find yourself wishing you were on the other boat. I felt that longing for our second prototype when paddling in rough water, but not so in flat water. The next prototype was an attempt the improve the flat water performance, and to improve the ergonomics of the deck. The boat was very comfortable, but still lacking in flat water performance. Three modifications later, an improved entry solved the problem.

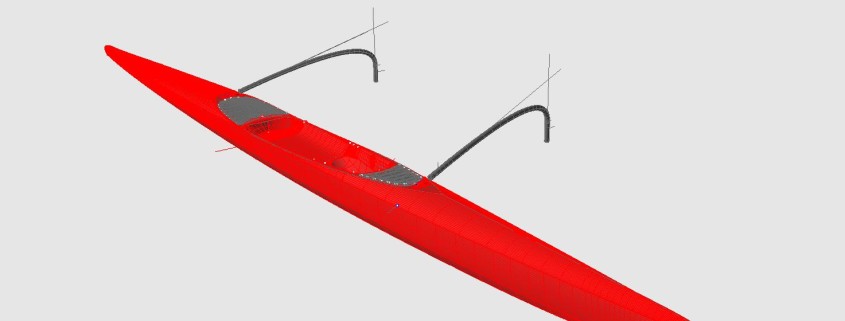

The final design on the Storm incorporates the deck from the third prototype and the modified and redesigned hull of the second. We also have two new ama designs, one for flat water and one for rough water. The Storm will come with interchangeable carbon fiber iakos, much like the ones on the Hurricane, but with more clearance underneath them. It will feature a new composite rudder system which is extremely lightweight, and very responsive. The footbrace and foot-pedals feel like your favorite slippers, and the adjustable seat is just right.

The most exciting new feature of the canoe is its construction. The Storm will be the first outrigger canoe to be molded in one piece. Traditionally canoes are molded in halves then joined with epoxy putty. Joining the canoe is a blind process which relies on excess putty to assure a good bond. Molding the canoe in one piece will eliminate excess weight and result in a stronger canoe. For the past few years we’ve been using prepregs without really exploiting their advantages. The new construction makes use of these advantages.

We’ve also been working on our finishing process. We’ll be doing more clear finishes, metallics, and custom graphics. In the past, our finishing has been one of our weaknesses. Our new factory manager, Brian Dalbey, formerly ran Board Works, which manufactured thousands of surf and windsurf boards with custom graphic designs. He brings his expertise in finishing with him.

So when will they be available? We expect the first ones out by the end of September. We ship to a lot of places, so they will not be available everywhere right away. Are they worth the wait? Absolutely.